Simulation Platform for Railway Systems

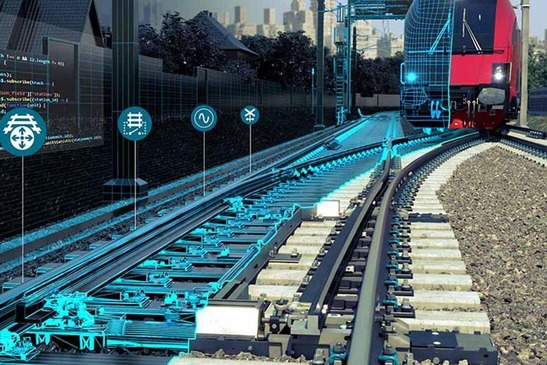

A FULLY VIRTUAL ASSESSMENT OF THE BEHAVIOUR OF THE RAILWAY INFRASTRUCTURE SYSTEM

The Rail4Future Platform is built to enable, for the first time, a fully virtual assessment of the behavior of the railway infrastructure system by deploying large-scale simulations based on hybrid-models enhanced with AI capabilities, real-time data input from the railway operations and visual-analytics methods.

Simulation Platform for Railway Systems

A MACHINE-LEARNING-BASED SURROGATE MODELING METHODOLOGY FOR SUBMODEL INTEGRATION IN THE HOLISTIC RAILWAY DIGITAL TWIN PLATFORM

A holistic railway infrastructure digital twin (DT) platform is sophisticated and consists of a series of submodels (e.g., turnouts, tracks, vehicles, etc.) that are built through various methodologies and software. However, integrating these submodels into the DT platform is tremendously challenging due to considerable computational complexity, software and interface restrictions.

Simulation Platform for Railway Systems

A REINFORCEMENT-LEARNING-BASED PARAMETER TUNING METHODOLOGY FOR

TRACTION CONTROL IN THE HOLISTIC RAILWAY DIGITAL TWIN SYSTEM

Holistic railway digital twin systems can optimize railway performance by merging diverse models and data for monitoring, diagnostics, and prognostics. In such systems, traction control is critical for safe and efficient train operations to prevent wheel slipping.

Simulation Platform for Railway Systems

VISUALIZATION FOR EXPLORATION

In the subproject Visualization for Exploration of the Rail4Future project, we successfully developed a user-centered visualization framework designed to handle complex, large-scale models and simulations. This framework is flexible, allowing for the seamless addition of new use cases and assets. The customizable dashboard includes maps, charts, and simulation planning tools, which are essential for users to draw meaningful conclusions from data.

Simulation Platform for Railway Systems

DIGITAL TWIN PLATFORM OF A HOLISTIC RAILWAY INFRASTRUCTURE SYSTEM

In railway industries, reliability and safety is of utmost importance since millions of passengers and megatons of goods are transported to their destination each day. This results in wear and tear of all involved assets, leading to enormous costs in maintaining the infrastructure and rolling stock. To ensure a bright future for railway systems, simulations are a helpful tool since they can provide accurate predictions of potential failures and help to optimize the planning of maintenance cycles.

Reliable Railway Tracks

PLASTICITY AND WEAR AT CROSSING NOSES

In railway turnouts, crossings and switches, significant dynamic loads lead to substantial changes of crossing nose profiles. To predict these changes, the so-called Whole System Model (WSM) was developed. There, multi-body dynamics (MBD) simulations, usually performed in Simpack, would interact with Finite Element (FE) simulations. The latter in particular proved to be computationally very demanding, resulting in simulation times of several weeks. To replace these simulations and significantly improve the efficiency of the WSM, the Semi-Physical Plasticity and Wear (SPPW) metamodel was developed in the Rail4Future project.

Reliable Railway Turnouts

DESCRIPTIVE APPROACH WITH STANDARD MEASURING CAR

The descriptive approach aims to prepare and intersect existing data sources in such a way that a condition assessment of turnout components and a prediction of maintenance activities that will be necessary in the future is possible. A prerequisite for this is sufficient data quality; if this is not ensured, conclusions cannot bring any added value. If sufficient data quality is given, but in the wrong form or without the correct localization, appropriate processing methods can remedy the situation.

Reliable Railway Tracks - Smart Rail

CONDITION MONITORING FOR PREDICTIVE MAINTENANCE WITH SMART ASSETS

Continuously welded tracks have become the standard in recent decades, offering numerous advantages over rails with gaps between the joints, such as easier maintenance, higher speeds, less wear on wheels and longer rail lifetimes. Seasonal temperature changes cause longitudinal expansion, which induces longitudinal stresses in the rails and in extreme cases can lead to rail breakage (winter) or track distortion (summer). Both phenomena have caused trains to derail in the past. To reduce the loads on the rails in temperatures classified as critical, train speeds are often reduced. However, this leads to economic losses and delays. In order to better assess both the risk of derailment and the need to set up a slow-speed section, it is essential to know the condition of the rails and to be able to assess and describe the state of stress. The neutral temperature was introduced for this purpose.

Reliable Railway Bridges

RELIABLE STEEL RAILWAY BRIDGES WITH EXTENDED SERVICE LIFE

EXCEPTIONAL FATIGUE AND FRACTURE TESTS ON A FULL-SCALE BRIDGE STRUCTURE CONSTRUCTED IN 1957

Steel railway bridges are an important part of the rail infrastructure. To minimise maintenance and repair efforts during operation, theoretical prediction models for reliability and robustness of bridges are very important. In addition, these models should allow to determine extended service lives for the individual bridges, to act resource-efficient and to be in line with solutions to respond to climate change. In the current research project, within Area 3.1, comprehensive procedures were developed und verified, to integrate also specific measurement data of the railway line and the bridge structure (e.g., operating service trains, stress-time histories due to train passage, early measurement of fatigue cracks), in order to get improved predictions.

Reliable Railway Tunnels

150 YEARS SAFETY ASSESSMENT OF TUNNELS

Given the global economic and ecological challenges arising from global warming, with a considerable contribution coming from the building industry, tunnel structures are required to be built in a sustainable way, allowing for safe operation over as many as 150 years. As of now, correspondingly tailored standardized computational procedures are not in place, associating the aforementioned requirement with yet other challenges. Rail4Future has opened avenues for 150 year-safetyassessment of tunnel structures, by combining a firstof-its-kind long-term material testing protocol with novel material mechanics approaches for the intricate behavior of CEM II concretes, the latter being characterized by a reduced carbon footprint.

Reliable Railway Tunnels

ANALYTICAL MECHANICS FOR TUNNEL SHELL UTILIZATION AND GROUND PRESSURE

Rail4Future gave rise to a major paradigm change in tunnel load assessments, yielding a new dimension of comprehensiveness, transparency, and reliability. It rests on a shift from ad-hoc choices concerning the nature of displacement fields in tunnel shells, to a rigorous mathematical representation of the kinematic and mechanical characteristics of cylindrical shells; and from a purely computational (digital) approach to closed-form analytical expressions, not only for stresses and strains throughout the monitored tunnels shells, but also for normal and shear traction forces (“ground pressure” and “ground shear”) acting from the ground onto the outer surface of the tunnel shell.